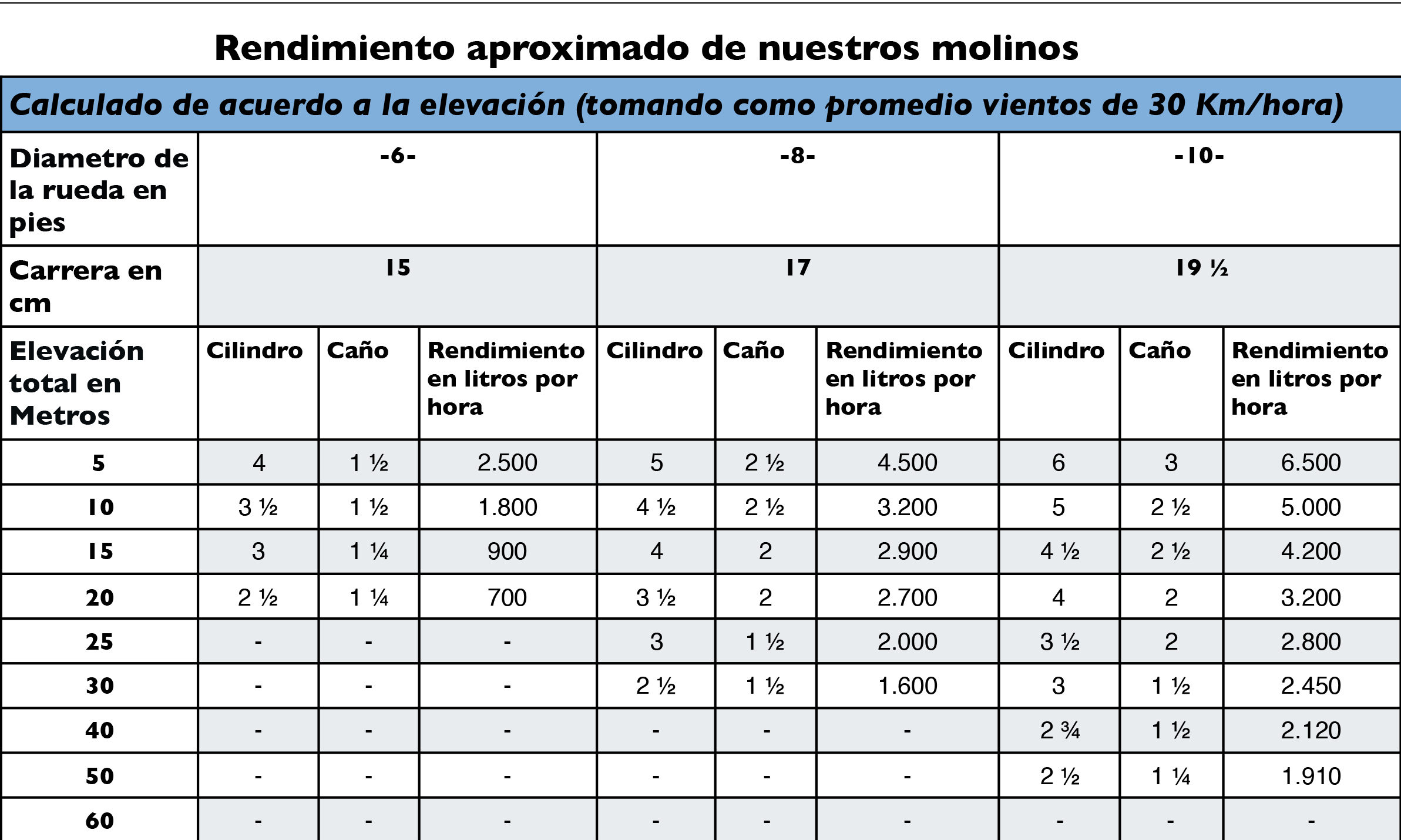

Mills HERCULES model 75 and 90

The technology used in the manufacture of our entire line of products is latest generation. CAD computers are used for the design and optimization of parts and materials, numerical control lathes, cutting and bending of sheet metal automatic, remachadoras de precisión. Thanks to the use of this technology implemented and the constant training of our technicians, more than 10 countries around the world use our products with optimal results.

The main shaft

The main axis on which you placed the drive wheel, It is of robust construction, made into a piece of steel that rotates on two bronze bushings.

Motion transmission

Through the crank turns the rotary motion of the drive wheel and its axis, in in vertical linear motion and is transmitted to the slide in whose centre is strongly fixed rod that actuates the pump piston. This double gear device gets a perfectly balanced distribution of the effort applied on the slide which operates the pumping rod.

rotating system

The rotating system has been built in the classical system, It consists of a cup with friction washer on which rests the entire machine being protected against dust, by its solid flange at the bottom of the mechanism housing. By this it allows the wheel to easily orient facing the wind with the softer or defend breeze wind gusts of hurricane force, being folded at the same time, to return to its normal position as wind speed decreases, whereby the speed of rotation of the wheel is automatically adjusted.

The box and its protection mechanism

The machine of our mills is contained in a solid carter, covered by a galvanized sheet which puts the mechanism from dust, water and foreign objects that could damage the functioning.

Lubrication

Lubrication we attach fundamental importance in the life of all parts and this is carried out by constant oil bath, filling consisting of the mechanism housing with lubricant to a certain level.

Brake

The brake, Large surface action, covers almost the entire periphery of the wheel hub and is provided with an adjustable system that allows pressure is carried out gradually until completely immobilize the wheel if you want that it does not rotate at all the mill being closed.

The wheel

In the manufacture of the wheel we have had in mind the importance of the functioning of this part.

A good wheel is the one that has a great power of uptake of air currents and whose palettes are built and positioned so that the soft breeze put it in motion. The number of blades, its size, weight and angle of attack are the result of a careful study.

Molino HERCULES

Hurricane Mills